ما الذي تبحث عنه?

عملية بناء الجدار الاستنادي وحجر الجدار ذو المناظر الخلابة

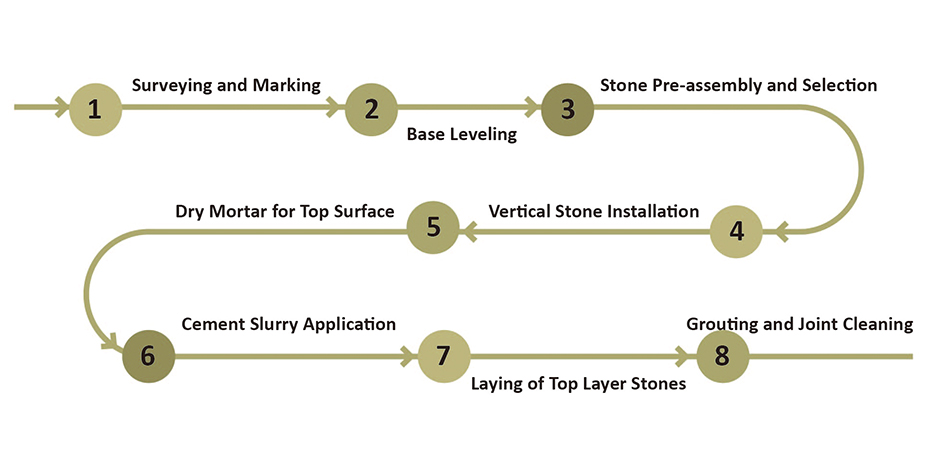

Jan 06, 20251. تدفق العملية

1) المسح ووضع العلامات:

قبل تركيب الحجر للجدار الخلاب والجدار الاستنادي، يتم إجراء مسح على طول الخط المركزي (أو الحدود) للجدار بناءً على الارتفاع المصمم، مع تحديد نقطة تحكم كل 5 - 10 أمتار. يجب إجراء القياسات وفقًا لمخطط التصميم أو رسومات البناء، مع تحديد خط الوسط وخطوط المستوى الأفقي وخطوط الشبكة.

2) تسوية القاعدة:

وفقًا للوضع المقاس والارتفاع، قم بتسوية القاعدة. إذا كانت القاعدة بها عيوب، استخدم الملاط الأسمنتي (للجدران) أو الخرسانة الحجرية المكسرة (للسطح العلوي) لتسوية القاعدة ومعالجتها.

3) التجميع المسبق للحجر واختياره:

جميع الأحجار المستخدمة في المشروع يجب أن تتم معالجتها في المصنع حسب الرسم التخطيطي وترقيمها وتعبئتها. بعد وصول الحجارة إلى الموقع وتفريغها، يجب فحص كل قطعة على حدة. يجب أن يتم فصل الأحجار المكسورة أو التي فقدت زواياها وإعادة معالجتها من قبل المصنع.

بمجرد الانتهاء من اختيار الحجر، قم بالتجميع مسبقًا في الموقع. يضمن التجميع المسبق محاذاة الألوان والأنماط والأنسجة وتطابق الدرزات بإحكام. يجب ترقيم الحجارة المجمعة مسبقاً في اتجاهين وتخزينها في أكوام حسب الفئات لاستخدامها في المستقبل.

4) تركيب الحجر العمودي:

(1) الأحجار الصغيرة الحجم:

في قاعدة رطبة، ضع طبقة واحدة من ملاط الأسمنت النقي (مع 10% وزنًا من 108 غراء مخلوط بالماء) ثم ضعه وهو لا يزال رطبًا.

للملاط الأساسي، استخدم نسبة 1:3 من الأسمنت والرمل، بسمك حوالي 12 مم، ويتم تطبيقه على طبقتين: الطبقة الأولى بسمك حوالي 5 مم والطبقة الثانية بسمك حوالي 7 مم. بعد ضغط الملاط الأساسي وتنعيمه، قم بخدش سطح الملاط.

بمجرد وضع الملاط الأساسي، ضع علامة على الخطوط الخاصة بكل قسم من الحجر. ضع ملاط أسمنتي بسمك 2-3 مم (مع 20% من وزن 108 غراء) على الجزء الخلفي من الحجارة المبللة مسبقًا وقم بتثبيتها (بدلاً من ذلك، يمكن استخدام مسحوق لاصق). اضغط بمطرقة خشبية لضمان المحاذاة واستخدم أداة المستوى للتحقق من الاستواء والاستقامة.

(2) أحجار كبيرة الحجم:

للأحجار التي يزيد حجمها عن 40 ملم من أي جانب، أو إذا تجاوز ارتفاع التثبيت 1 متر، يتم استخدام طريقة التثبيت التالية:

أ. الحفر والنحت:

قبل التثبيت، استخدم آلة حفر لحفر الثقوب وفقًا لمتطلبات التصميم. قم بتأمين إطار خشبي لمحاذاة لقمة الحفر مع الحافة العلوية للحجر. حفر ثقوب عند 1/4 عرض الحجر من كل طرف. لكل سطح، قم بحفر فتحتين بقطر 5 مم وعمق 12 مم. وينبغي أن يكون مركز الحفرة على بعد حوالي 8 ملم من الجزء الخلفي من الحجر.

إذا تم استخدام الجرانيت وكان عرض الحجر كبيرًا، قم بزيادة عدد الثقوب. بعد الحفر، قم بإزميل طفيف بعمق 5 مم حول الثقوب لتشكيل شكل "خرطوم الفيل" لتضمين الأسلاك النحاسية أو المجلفنة.

بالنسبة للأحجار الكبيرة، وخاصة الجرانيت الجاهز، إذا كان من الصعب ربط سلك الرصاص المجلفن أو السلك النحاسي في الطرف السفلي، فاستخدم مطحنة رفيعة صغيرة محمولة (4 - 5 مم) لإنشاء أخاديد (طول 3-4 مم تقريبًا و12 مم) عميق) على ارتفاع 1/4 من الحجر على كل من السطحين العلوي والسفلي.

ب. خيوط أسلاك الفولاذ أو أسلاك الرصاص المجلفنة:

قم بقطع السلك النحاسي المجهز أو سلك الرصاص المجلفن بطول 20 سم تقريبًا. ثبت أحد طرفي الحفرة باستخدام راتنجات الإيبوكسي وإسفين خشبي، ثم ثبته بإحكام. وينبغي ثني الطرف الآخر ووضعه في الأخدود، مع ضمان عدم بروز السلك من أعلى الحجر أو أسفله للسماح بالتماس محكم مع الحجارة المجاورة.

ج. ربط شبكة الصلب:

أولاً، قم بإزالة القضبان الفولاذية المدمجة من الجدار وقم بتنظيف منطقة التثبيت. ابدأ بربط حديد التسليح العمودي (φ6) وتثبيته على الحائط باستخدام القضبان الفولاذية المدمجة.

بالنسبة للفولاذ الأفقي، استخدمه لربط ألواح الجرانيت المصقولة. على سبيل المثال، بالنسبة للبلاطة التي يبلغ ارتفاعها 60 سم، يتم ربط الشريط الأفقي الأول على ارتفاع 10 سم فوق سطح الأرض ويستخدم لتأمين السلك النحاسي أو المجلفن السفلي للطبقة الحجرية الأولى. يتم ربط الشريط الأفقي الثاني على مستوى 50 سم، أسفل الحافة العلوية للحجر بمقدار 2 – 3 سم، لتثبيت السلك النحاسي أو المجلفن أعلى الطبقة الأولى. استمر كل 60 سم بقضبان أفقية إضافية.

د. علامة الخط:

استخدم عمودًا شاقولًا لتحديد المحاذاة الرأسية لجدار الجرانيت المصقول من الأعلى إلى الأسفل. ضع في اعتبارك سمك ألواح الجرانيت، وفجوة الملاط، والشبكة الفولاذية. يجب أن تكون الفجوة بين جلد الجرانيت وسطح الهيكل 5 - 7 سم.

بعد المحاذاة الرأسية، ضع علامة على الخطوط العريضة لتركيب الحجر على الأرض. يعمل هذا المخطط كخط مرجعي للطبقة الأولى من الحجر. ضع ألواح الرخام أو التيرازو الجاهزة على طول الخط المرجعي المحدد مع وجود فجوة بمقدار 1 مم بين كل حجر (إذا كانت محددة، اضبط الفجوة وفقًا للتصميم).

ه. تركيب الحجر:

اختيار القطع الحجرية ومحاذاة السلك النحاسي أو المجلفن وتثبيت الحجارة. يجب أن تكون الحافة العلوية للحجر مائلة قليلاً إلى الخارج. أدخل يدك خلف الحجر لربط السلك النحاسي أو المجلفن الموجود أسفل الحجر بالحديد الأفقي.

لا تقم بشد السلك أكثر من اللازم؛ ترك بعض الركود. سيتم تثبيت الحجر بمجرد تطبيق الجص. ضع الحجر في وضع مستقيم وقم بتثبيت السلك النحاسي أو المجلفن العلوي. استخدم أسافين خشبية لتثبيت الحجر واترك مسافة 30 - 50 ملم بين الحجر والقاعدة للحشو.

استخدم أداة المستوى للتحقق من المحاذاة الرأسية والاستواء. إذا كانت هناك أي فجوة أو عدم انتظام، استخدم رقائق الرصاص للبطانة وتأكد من وجود مسافة موحدة. التأكد من بقاء الحافة العلوية للطبقة الأولى من الحجارة مستقيمة.

بعد التأكد من المحاذاة، قم بتحضير الجبس في وعاء وضعه كعجينة بين طبقتي الحجر لربطهما معًا. يمكن أيضًا استخدام الأوتاد الخشبية لتثبيت الحجارة. بعد أن يتصلب الجبس، يمكن مواصلة عملية الحشو (إذا لزم الأمر، أدخل أنابيب بلاستيكية قبل الحشو).

ف. الحشو:

قم بتحضير خليط من الأسمنت والرمل بنسبة 1:2.5 وأضف الماء لتكوين ملاط بسماكة 8 - 12 سم. اسكب الجص ببطء أثناء استخدام مطرقة مطاطية للنقر على الحجارة بلطف لطرد الهواء وضمان الالتصاق المناسب.

يجب ألا تتجاوز الطبقة الأولى من الجص ثلث ارتفاع الحجر، وبشكل عام حوالي 15 سم. من المهم التأكد من أن الجص لا يسبب إزاحة الحجارة. في حالة تحرك أي حجارة، قم بتفكيكها وإعادة تركيبها على الفور.

بعد مرور ساعة إلى ساعتين، تحقق من الحركة قبل وضع الطبقة الثانية من الجص، والتي يجب أن يكون ارتفاعها حوالي 20 - 30 سم. بعد الإعداد الأولي، استمر في الحشو حتى يصل الارتفاع إلى 5 - 10 سم من أعلى الحجر.

5) وضع حجارة السطح العلوي:

قم بتنظيف الحجارة وانتظر حتى يصل الملاط الحجري العمودي إلى القوة الكافية. بعد ذلك، يتم وضع طبقة من الملاط الجاف (خليط أسمنتي 1:3) على السطح العلوي، مع التأكد من ضغطها وامتدادها بمقدار 3 مم فوق سطح الحجر العمودي و100 - 300 مم خلف حافة الحجر. رش ملاط الأسمنت النقي فوقها، ثم ضع الحجارة العلوية، ثم اضغط برفق بمطرقة مطاطية لطرد الهواء.

6) تنظيف المفاصل:

بعد تركيب جميع الحجارة، قم بتنظيف أي بقايا من الجبس باستخدام قطعة قماش لمسح السطح. قم بإعداد الجص من اللون المطابق وملء الفواصل، وقم بالتنظيف أثناء التقدم لضمان التماس موحد ومشدود ونظيف.

2. معايير الجودة:

1) يجب أن يكون تركيب الحجر مسطحاً وثابتاً.

2) أن يكون القوام متناسقاً وناعماً.

3) فحص المظهر: لا ينبغي أن يحدث أي رفع، ويجب أن يكون الحشو (ملء المفاصل) كاملاً.

4) العناصر المقاسة:

| جدول الانحراف المسموح به لتركيب الحجر | |||

| رقم | العنصر | الانحراف المسموح به (مم) | طريقة التفتيش |

| 1 | تسطيح السطح | 2 | تحقق باستخدام مسطرة 2 متر ومقياس حشو على شكل إسفين |

| 2 | محاذاة المفاصل | 3 | تحقق باستخدام خط 5 أمتار ومسطرة فولاذية |

| 3 | فرق ارتفاع التماس | 0.2 | تحقق باستخدام مسطرة فولاذية ومقياس حشو على شكل إسفين |

| 4 | عرض الفجوة بين الحجارة | ≥2 | تحقق باستخدام مسطرة فولاذية |